ماده مركب چوبی محسوب می شود با جرم حجمی بین 500 تا 800 كیلوگرم بر متر مكعب ( به طور متوسطKg/M3 750 ) كه از مواد مختلفی می تواند تهیه شود . در جهان بیشتر MDF ها بر پایه چوب تهیه می شوند و از چوبهای نرم مثل درخت كاج استفاده می گردد

اساس تركیب MDF چوب و رزین است كه تحت فشار و حرارت قرار گرفته و با افزایش استحكام ، مقاومت در برابر آتش و نفوذ ناپذیری خواص بهتری نسبت به چوب نرم خوا هد داشت همچنین قابلیت ماشین كاری بالای نیز دارد كه قبل از این تنها چوبهای سخت قابلیت كارهای مكانیكی و ماشین كاری را دارا بودند. MDF ها به طور معمول دارای با ضخامتی از 3 میلیمتر تا 40 میلیمتر می باشند.

امروزه علاوه بر چوبهای نرم از دیگر مواد نظیر ساقه غلات ، برنج ، نی ، نیشكر ،چوبها و كاغذهای غیر قابل مصرف و … برای تهیه تخته صنعتی استفاده می شود. MDF تولیدی از چوب دارای كیفیت بهتری از سایر انواع MDF می باشد. MDF تهیه شده از باگاس نیشكر نیز از قاعده مستثنی نمی باشد ولی از نظر كیفی در سطح جهانی در رده چوب طبقه بندی شده است. در مقایسه با نئوپان،MDF دارای جرم یكنواخت تری در سطح ورق است همچنین از صافی سطح و قابلیت سنباده زنی و اصلاح سطح برخوردار است MDF به صورت خام و روكش شده به بازار عرضه می گردد MDFهای مسطح در ساخت مبلمان اداری ، كابینت ، تزئینات داخلی چوبی كاربرد فراوان دارن

MDF یک محصول پانلی است که از ترکیب الیاف لینگوسلولزی با رزین های مصنوعی یا هر نوع چسب مناسب دیگر تولید می شود. این پانل ها از دانسیته 496 تا 801 کیلو گرم بر متر مکعب (50-31 پوند بر فوت مکعب) در پرس داغ فشرده می شوند. چسبندگی داخلی کامل پانل به وسیله رزین مصنوعی و سایر چسب های آلی حاصل می شود.

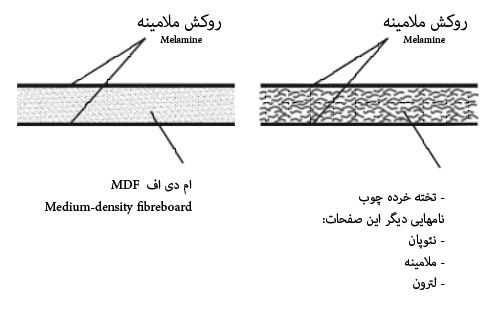

در مقایسه با تخته خرده چوب، MDF دارای دانسیته یکنواخت تر در سراسر تخته و لبه های صاف تر و منسجم تر است که در نتیجه آن بهتر می تواند مورد ماشین کاری قرارگیرد. محصول نهایی می تواند به صورت سطح صاف و یا با رگه های دلخواه طرح چوب و… باشد که در این صورت نیاز به روکش شدن (با روکش طییعی و یا لمینت) مرتفع می شود.

(Medium Dencity Fibernation) مخفف MDF است. MDF فیبر با چگالی متوسط است که بصورت فشرده از ضایعات چوب تهیه می گردد و از مقاومت زیادی در مقابل رطوبت برخوردار است.MDFهمواره به عنوان مغز و درون کار در صنعت چوب مورد استفاده قرار می گیرد. آن چه MDF را زیبا می سازد پوشش روی آن است که بسته به نوع کارمتفاوت می باشد. از معروفترین روکش هایMDF می توان PVC ، VINILIUM، HPL و فرمیکا را نام برد. لازم به ذ کر است فرمیکا بسته به نوع ضخامتش متفاوت می باشد.

بنابراین هرچه از روکش های ضخیم تر و مقاوم تر در پوشش MDF استفاده شود جنس مرغوب تری بدست خواهد آمد. MDF نوعی فیبر است که از خرده چوب به هم فشرده تحت فشار و حرارت به وجود می آید. اکنون در بیشتر موارد سازندگان کابینت از MDF به جای تخته سه لائی یا تخته های نئوپان استفاده می کنند.

اما بدلیل ارتقا سطح کیفی MDF نسبت به سایر محصولات مشابه آنرا متمایزتر نشان داده و بخودی خود از جایگاه خاصی برخوردار نموده زیرا این محصول ضمن قرار گرفتن در خانواده تخته های سخت، مقاومت کاربردی بالاتر نیز دارا می باشد. از طرفی بدلیل اینکه سطح MDF صاف، یکنواخت و نرم بوده و ترکیبی از فیبرهای چوبی لیگنو سلولزی می باشد در برابر گرما و فشار سخت شده و در صورت مخلوط شدن با سایر افزودنی ها کمک شایانی به ارتقاء سطح کیفیت آن می شود تا بتوان در ساخت کابینت آشپزخانه، مبلمان، میزو صندلی، اثاثه اداری و… از آن بهره جست.

ام دی اف را پس از تولید میتوان روکش نمود. روکشهای تزیینی علاوه بر زیبایی به دوام و کاربرد آن در محیطهایی مانند آشپزخانه کمک میکند. روکش ملامینه متداول ترین نوع روکش برای MDFمیباشد که در آن فرایند کاغذ دکوراتیو آغشته به رزین تحت فشار و حرارت بر روی تخته چسبانده میشود.

این محصول ضمن دارا بودن خواص شبیه سایر اوراق فشرده چوبی دارای برخی خواص برتر نیز می باشد كه باعث ارتقاء بازار آن در بین سایر اوراق فشرده چوبی مانند تخته خرده چوب (نئوپان)، تخته لایه، تخته فیبر سخت و … شده است . در واقع این محصول (MDF) ابتدا بعنوان جایگزین اوراق فشرده چوبی مطرح بوده و سپس در كاربردهای جایگزین چوب نیز بكار رفته است. در حال حاضر دامنه كاربردهای آن روز به روز در حال افزایش است .

از جمله خصوصیاتی كه باعث ایجاد كاربردهای متنوع (MDF) شده عبارتند از :

-

- خصوصیـات فیزیـكی و مكـانیكی بالا

-

- دامنه وسیع دانـسیـته (وزن مخـصوص) ، ضخامت و ابـعاد MDF قابل تولید

-

- قابلیت ابزار خوری ، ماشین كاری و سنباده زنی

-

- سطوح صاف و متراكم

-

- قابلیت شكل پذیری و لبه های صاف

-

- عدم وجود معایب چوب

-

- پروفیل دانسیته یكنواخت و همگن

-

- قابلیت انجام رو سازی های مختلف همچون انواع روكشی های چوبی و غیر چوبی، رنگ آمیزی و غیره

-

- پایداری ابعاد و مقاومت به فشرده شدن

-

- زیبایی ظاهری، طبیعت ملایم و ظریف و حالات شبیه به چوب

-

- قیمت مناسب

مقایسه MDF و Letron با چوب طبیعی

به دنبال ورود MDF و لترون به صنعت چوب ، تحولی شگرف در این صنعت به وجود آمد که توانست صنعت چوب را از ورطه سنتی و محدودیتهای فراوان رهایی بخشیده و وارد دنیای صنعتی و مدرن ، همراه با کیفیت بالاتر ، گرداند.در اینجا به بیان مختصری از خصوصیات لترون و MDF در مقایسه با چوب طبیعی می پردازیم:

1 ) مصنوعات چوبی ساخته شده می بایستی رنگ آمیزی شده و هزینه ها و دشواریهایی را جهت محافظت سطح آنها می بایستی متحمل شد.در فرایند رنگ آمیزی نیز مواد شیمیایی بر بافت طبیعی چوب اثرات مخربی داشته و بعد از مدتی نیز رنگ قسمتهای مربوط به مفاصل و اتصالات به صورت لایه لایه خرد شده و یا بلند می شود.نور مستقیم خورشید نیز تاثیرات نامطلوبی بر سطوح چوبی خواهد داشت.در صورتی که لترون و ام دی اف نیازی به رنگ آمیزی نداشته و داری سطوح لعابی یا لامینت هستند که در برابر سایش ، برخورد و نور آفتاب و … مقاومتر هستند.

2 ) مصنوعات MDF و لترون به صورت اجزای قابل مونتاژ و قابل تفکیک ساخته می شوند و همین امر سهولت در جابجایی و محافظت آسانتر را در هنگام حمل ، پدید می آورد. در صورتی که در مصنوعات چوبی ، این امر با سادگی میسر نبوده و معایبی را به همراه دارد.

3 ) پروفیلهای MDF و لترون در سطوح مختلفی از مقاطع ساخته شده و می تواند در هر مرحله از ساخت ، متناسب با نوع محصول تغییر کند. حال آنکه در فرآیند تغییر مقاطع چوب طبیعی و برشهای مقطعی ، سختیها و موانع بیشتری وجود دارد و مستلزم زمان و هزینه بیشتری است .

مزایای استفاده از MDF بجای نئوپان

MDF بدلیل ساختار یکنواخت همگنی که دارد به راحتی ابزار کاری شده و تهیه پروفیل و برش کاری براحتی و بدون اتلاف و خرابی MDF امکان پذیر است. همچنین بواسطه داشتن سطح بسیار صاف و صیقلی قابلیت روکش کاری و رنگ شدن و خوبی دارد. در برابر رطوبت، پوسیدگی و همچنین خوردگی توسط حشرات از جمله موریانه کاملا مقاوم است. طول عمر بیشتری داشته و در برابر تغییر شکل و خمیدگی و پیچش مقاوم بوده از خاصیت ضد صدا Acoustic بر خوداری است. ضمن آنکهMDF در ضخامت پایین(5/2mm) نیز قابل تولید است: از کاربردهای MDF نازک یا Thin MDF می توان استفاده در صفحات پشتی کابینتها، پنل چارچوب در،پارتیشن بندی و مصارف جدید در صنعت کفش سازی، قسمتهای داخلی وسایط نقلیه، اسباب بازیها، تیغه های فنهای برقی و مدارهای برقی نام برد. از کاربرد MDF ضخیم یا Thick MDF علاوه بر ساخت اثاثیه و مبلمان، می توان استفاده در ساختمان سازی و ساخت ستونها و ارکهای داخل ساختمان نام برد. این نوع کاربرد بواسطه مقاومت MDF در برابر خمیدگی، پیچش و قدرت نگهداری پیچ عملی است.

مواد اولیه موردنیاز

چوب و مواد لیگنو سلولزی: نظیر چوب، تفاله نیشکر یا باگاس که چوب را می توان ازعمده ترین و مهم ترین ماده اولیه این صنعت محسوب نمود که لازم است هرگونه تغییری در عوامل تولید و واریته های چوب کاملا کنترل گردد تا بتوان در نهایت اثر بخش آنرا در کیفیت محصول نهایی لمس نمود ضمنا می بایست به نکات زیر نیز توجه خاص نمود:

-

- از انواع چوب ها بطور جداگانه یا مخلوط می توان استفاده کرد.

-

- چوب ها با قطر کم، شاخه ها و ضایعات استحصالی از جنگل مناسب می باشند.

-

- تراشه های رنده شده و یا خاک اره (حتی بعنوان پرکننده)

-

- استفاده از مواد لیگنو سلولز غیرچوبی که مازاد تولید محصولات کشاورزی را تشکیل داده و بخش الیافی گیاهان یک ساله را تشکیل می دهند. بعضی از این مواد نظیر الیاف تفاله نیشکر (باگاس) به سهولت در دسترس می تواند باشد بطوریکه در حال حاضر در مناطق جنوبی کشور دپو و انبار کردن آن بدلیل خود سوز بودن مشکلات زیست محیطی را نیز به همراه داشته که در صورت اندیشیدن تدابیر لازم ضمن حفظ سرمایه های ملی می تواند ارزش افزوده قابل توجهی را بدنبال داشته باشد.

مواد شیمیایی

عمده ترین ماده شیمیایی که در این صنعت استفاده می شود، رزین یا چسب می باشد که نقش (اتصال دهنده) را ایفا می نماید به عبارت دیگر متداولترین رزین قابل استفاده، فنل – فرم آلدئید و اوره فرم آلدئید می باشد که متناسب با کاربرد محصول نهایی رزین نیز تغییر خواهد کرد.

سایر مواد افزودنی

شامل مواد آهار زنی و مقاوم در مقابل جذب رطوبت بطوریکه منجر به افزایش مقاومت در برابر نفوذ رطوبت گردد و یا مواد حفاظتی که در مقابل آتش و عوامل هم ردیف از مقاومت بیشتری برخوردار گردد (معمولا آتش مستقیم مدنظر است). روش تولید و تشریح فرآیند برای ساخت و تولیدMDF نیازمند الیاف خشک چوب خواهیم بود. این الیاف با استفاده از دستگاههای ریفانیرهای معمولی تحت فشار اتمسفریک و ریفانیرهای تحت فشار بخار آب تولید می گردند. این تجهیزات توانایی استفاده از انواع خرده چوب، انواع ضایعات آن را خواهند داشت بطوریکه پس از قطع زنی و اندازه بری چوب آلات گرد و یا ضایعات و در صورت نیاز پوست گیری چوب، کاملا خرد شده و جهت طبقه بندی به قسمت الک ها روانه می شوند و مواردی که در اندازه های از پیش تعیین شده رسیده باشند به سیلوها هدایت شده و سپس تحت عملیات پخت و بخار زنی قرار گرفته تا آماده روانه شدن به دستگاه ریفانیر شوند. آنگاه چسب زنی صورت گرفته به قسمت خنک کاری هدایت می شود. ضمنا یادآوری می شود در قسمت الک ها، خرده چوب ها می توانند بازیافت مجدد شده و در مسیر فرآیند قرار گرفته و مواردی که قابل استفاده نمی باشند بعنوان ضایعات جمع آوری و به سایر مصارف رسانیده شود.

یکی از موارد قابل ذکر در این مرحله (یارد چوب) می باشد بعبارت دیگر عملیات تولید خمیر تخته فیبر نیازمند تغذیه پیوسته، یکنواخت و همگن می باشد زیرا در غیر اینصورت در کیفیت الیاف تولیدی تغییرات زیادی رخ داده و کیفیت محصول نهایی را تحت الشعاع قرار می دهد. برای دستیابی به تغذیه پیوسته چوب بطور یکنواخت و همگن می بایست از خرده چوب استفاده نمود. از طرف دیگر به منظور حصول اطمینان از تغذیه مداوم با سرعت ثابت لازم است که ماده اولیه موردنیاز جهت مصرف حداقل چندین ماهه ذخیره سازی گردد. (معمولا 3 تا 4 ماه) ضمنا یارد چوب شامل چوبهای هیزمی بطول 1 الی 2 متر بریده شده می باشد.